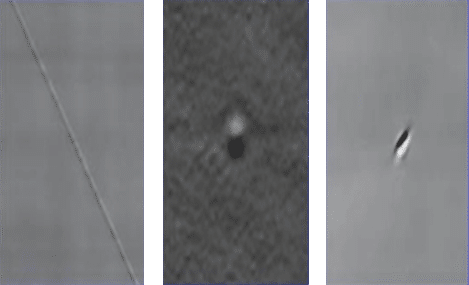

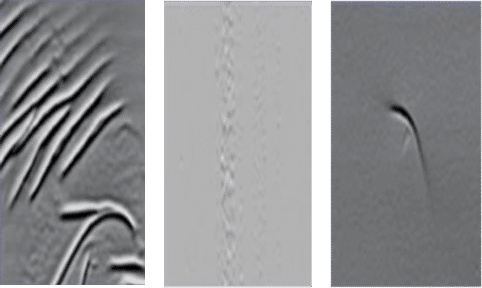

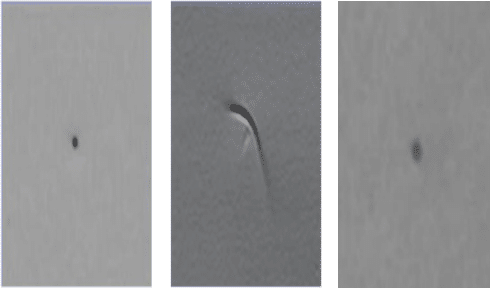

Advanced imaging and image processing algorithms are used to accurately identify major foil defects such as impurities, abrasions, bumps, pits, pinholes, mosquitoes, dirt and so on, enabling continuous foil surface quality control and classification and grading of surface defects. Inspection and classification of defects such as scratches, chromatic aberrations, oil spots, stains (coloured oil), insect spots, foreign objects, roll marks, white stripes, bright marks, streaks, chin marks, etc.

100% full coverage real time detection, real time sound and light alarm for occasional and intermittent defects, automatic shutdown when defects are found, shutdown threshold can be adjusted by defect category.

Defects good and bad chart comparison display, defect list display, defect distribution chart display.

Output defect information, defect information can be displayed in volumes, and each volume information can be queried and output by order number, time or volume number, etc.