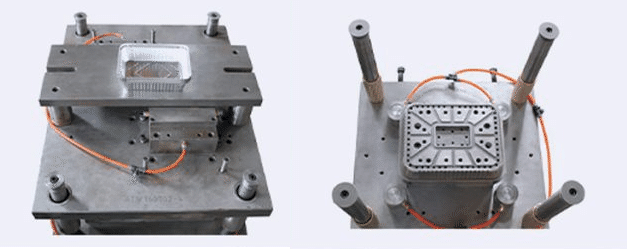

The thickness of aluminum foil lunch boxes is between 100% and 200% respectively, which can be divided into two types: wrinkled and wrinkle-free. It can also be divided into two types: disposable and reusable. It is usually called tin foil lunch boxes, and foil rolls are produced through a one-time automatic cold stamping process of equipment and molds.

It is 3 series or 8 series aluminum ingot raw materials, cold rolled or hot rolled into uniform thickness, smooth surface, no pinholes, no dust particles aluminum

In fact,

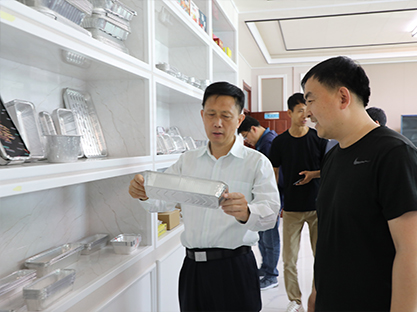

Aluminum foil lunch boxes are easy to process and form, convenient to seal, food hygiene, and good formability of aluminum boxes. In the process of medium-pressure containers, even in the wrinkled and curled parts, there will be no cracks and breaks of aluminum foil lunch boxes. According to the requirements, alloys of different shapes and thicknesses and aluminum structures in the heat treatment state can be selected to

accurately reflect the purpose of the product.

Aluminum foil food and containers can use the same aluminum foil cover, or paper or other material covers, using its easy deformation and corrugation points to achieve sealing, strong mixing and continuity protection ability, and can avoid food storage or contamination. For large-scale catering companies and kitchen distribution, the automatic capping equipment developed by aluminum foil manufacturers can be used to improve distribution efficiency, and the effect is significantly better than other materials.